Exothermic Welding

Exothermic Welding

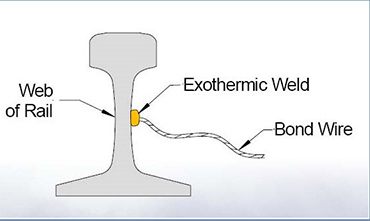

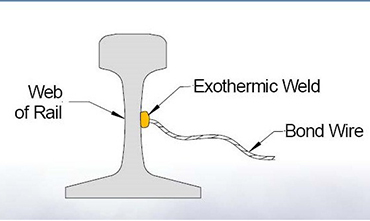

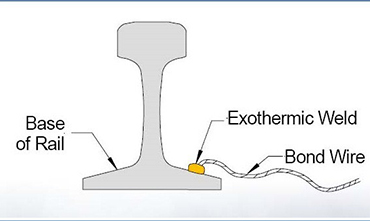

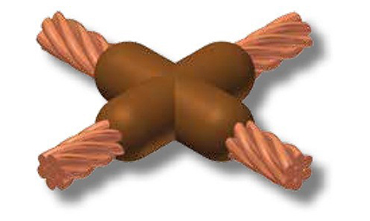

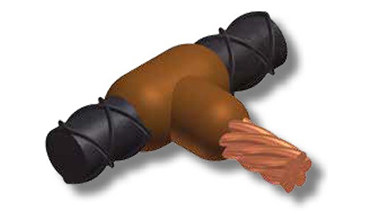

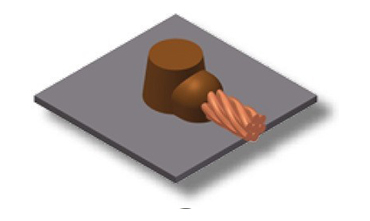

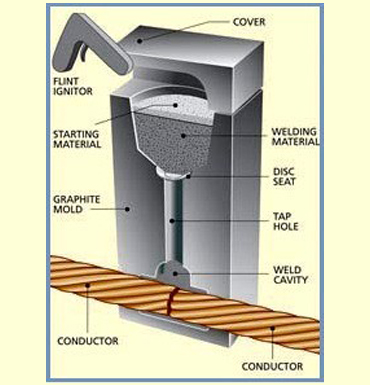

The exothermic welding process is a simple and efficient method of welding copper to copper or copper to steel. The welding process is a molecular weld. It has the same melting point as copper. The major advantage is that no external power is required in the process. It uses high temperature reaction of powdered copper oxide and aluminum. The reaction takes place in a semi-permanent graphite mold.

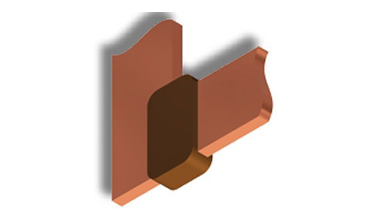

Mould

The mould is made of a semi-permanent graphite and is used for making the exothermic connection. Under normal usage, these high temperature graphite mould can last for an average of 100 or more connections.

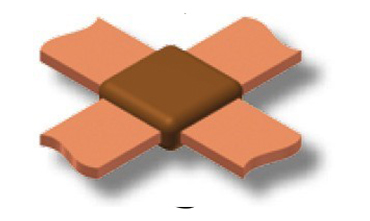

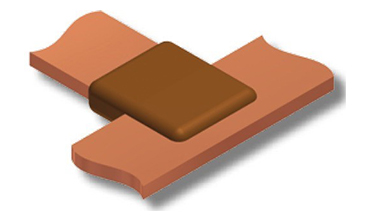

Weld Powder

This weld metal in powder form is the one which is melted along with steel Disc from the weld. Exothermic welding material used for electrical connections to rail shall contain weld material and starting material. The weld material alloy shall be specifically design for applications to rail. The weld material shall not contain tin. The starting material shall consist of aluminum, copper oxide and iron oxide. It shall not contain phosphorous or any caustic, toxic or explosive substance. The components of the exothermic welding material shall not be volatile or sensitive to shock, not shall they be capable of spontaneous ignition or ignition by friction.

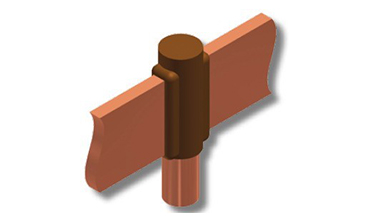

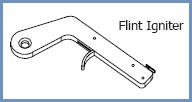

Flint Gun Igniters

When making a connection, Flint Igniters are used to ignite the starting material.

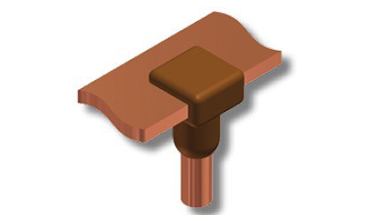

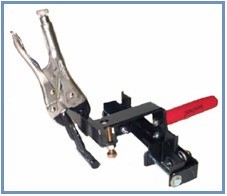

Mold Handle Clamps

Mold Handle Clamps are required for all molds for fixing and locking the mould to the right position.

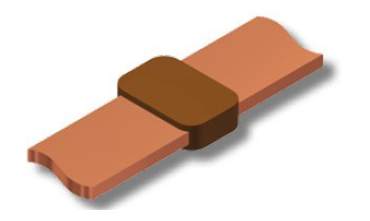

Mould Cleaning Brush

Slag can be cleaned from the moulds by using a mould cleaning spade. The mould cleaning brush is used to clean the graphite mold without damaging the mould.